Main Configurations

Gooch Thermal spiral heat exchangers are horizontally or vertically mounted and fitted with removable covers or welded extensions to make three different flow patterns for liquid to liquid or vapor to liquid services.

All three spiral heat exchanger types can be designed as column-mounted overhead condensers and multi-stage condensing towers directly welded or flanged atop distillation columns.

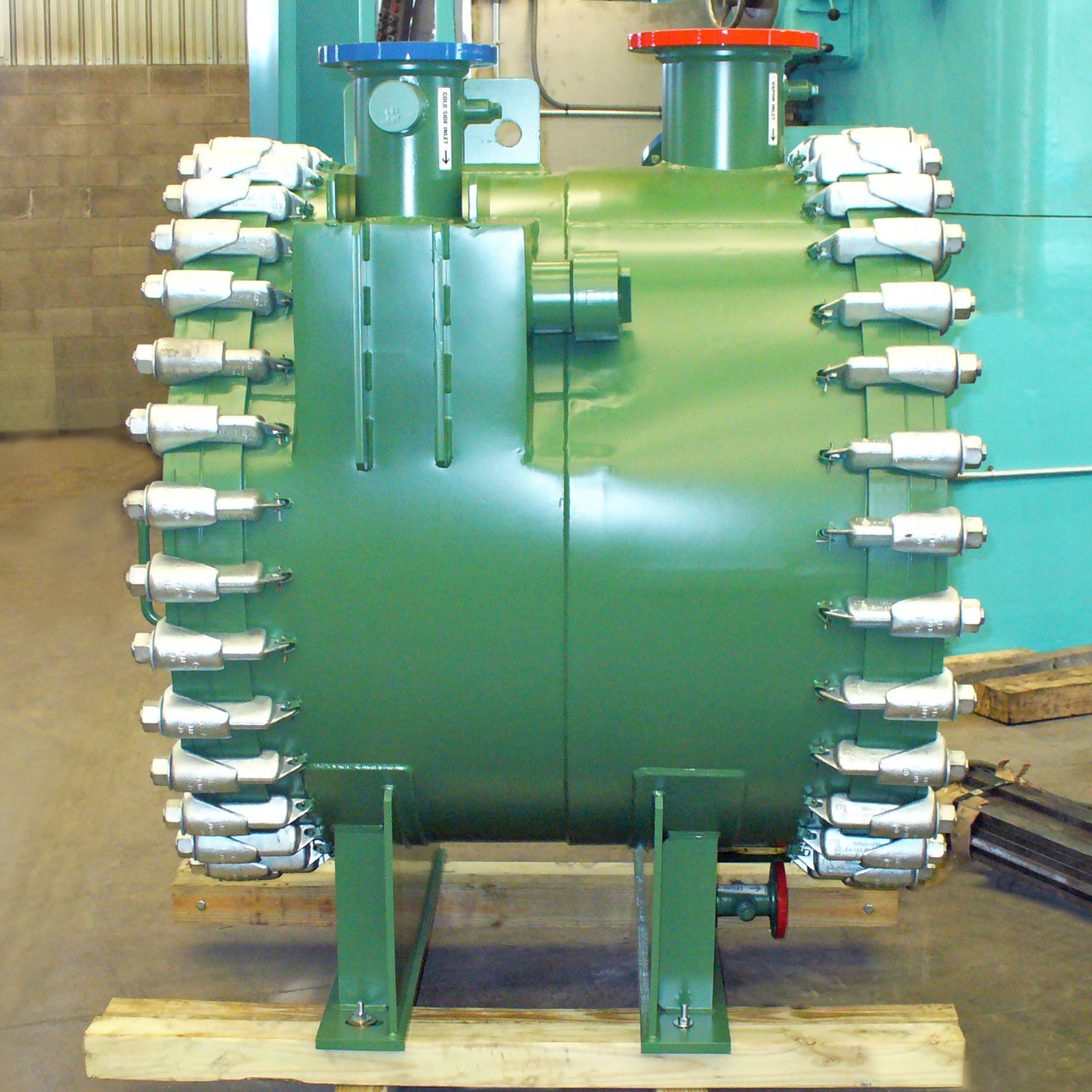

Type 1.1-H Spiral Heat Exchanger

Stripping Column Feed Preheater, Duplex 2205

Type 1: Spiral Flow Both Sides

- Liquid to liquid cooling, heating or heat recovery

- Steam heating or vapor condensing

- Suitable condenser at pressures above atmospheric

- Countercurrent or co-current flow

- Best for crossing or close approach temperatures

- Self-cleaning effect in both spiral passages

- Ideal for handling suspensions, slurries & sludge

- Removable covers for independent & easy access

Type 2-V Spiral Heat Exchanger

Column Overhead Condenser, 316/316L SS

Type 2: One Side in Cross Flow

- Ideal for condensing under deep vacuum

- Vapor in annular cross flow

- Cooling medium in spiral flow

- Extremely low vapor side pressure drop

- Large flow cross-section for large vapor volumes

- Short height of condensing section

- Suitable in liquid to liquid duty with large flow imbalance

Type 3.1-H Spiral Heat Exchanger

Viscous Product Steam Heater, Carbon Steel

Type 3: Combined Cross - Spiral Flow

- Vapor to liquid condensing

- Optimal for mixed vapors with inert gases

- Built-in internal subcooling section

- Suitable for low to moderate operating pressures

- Combines features of Types 1 & 2

- Excellent steam heater of viscous fluids & slurries in horizontal orientation