Manufacturing

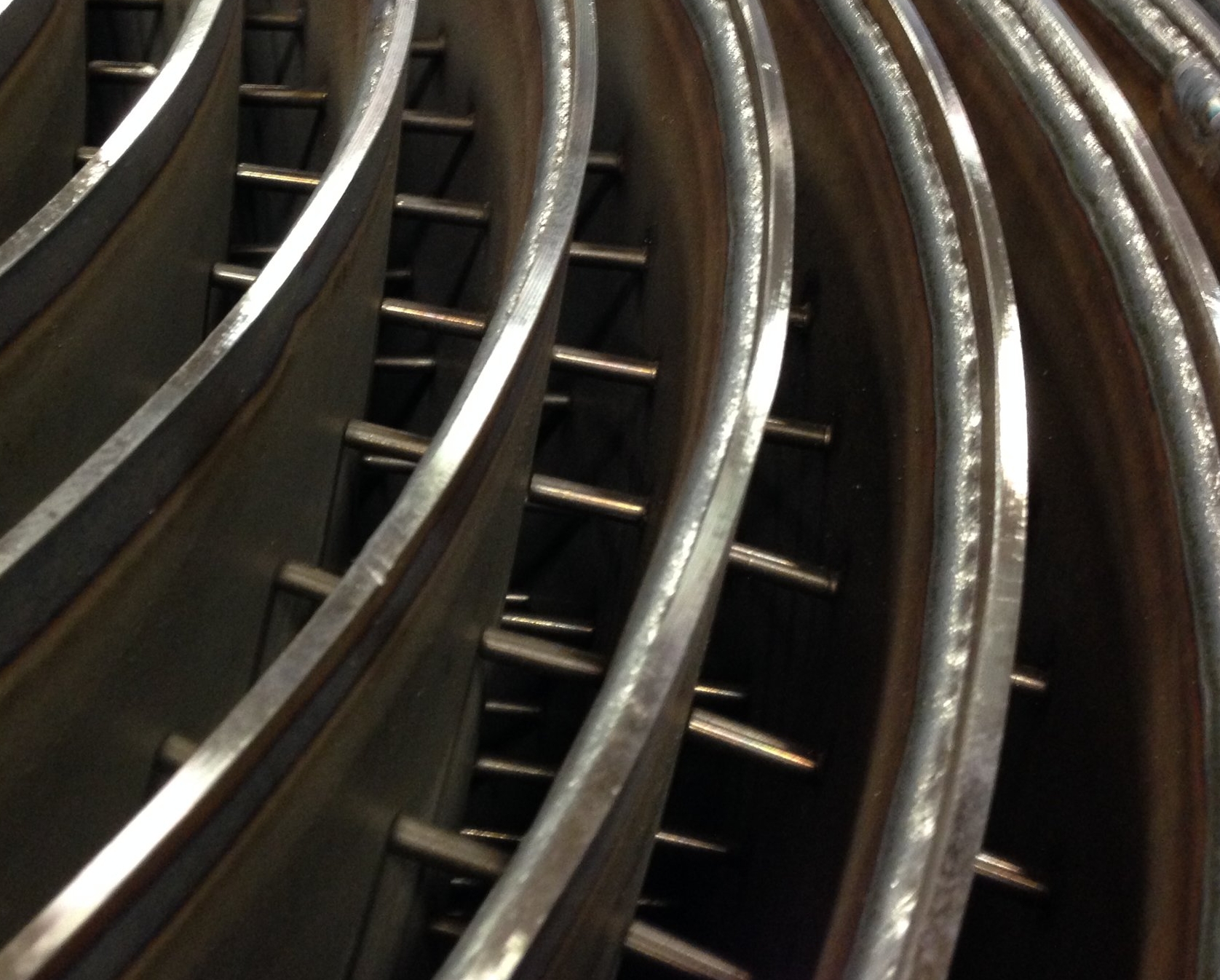

Gooch Thermal spiral heat exchangers are designed and built to ASME Code with U-stamp and registered with the National Board.

Our engineering and manufacturing services include inspections, failure analysis, and vessel repairs under our NBIC "R" Stamp.

Certificates of Authorization

ASME “U” Stamp

National Board “NB” Stamp

National Board “R” Stamp

In Canada, we comply with the Canadian Registration Number (CRN) requirements for all of the provinces and have many spiral heat exchangers in Alberta registered with ABSA.

We can also supply spirals built to other internationally recognized pressure vessel codes.

Spiral Heat Exchanger Design Data

Spiral Plate Width: 8" to 80" (200 to 2000 mm)

Spiral Plate Thickness: 0.08" to 0.25" (2.0 to 6.3 mm)

Channel Spacing (Plate Gap): 0.1875" to 1.5" (5 to 38 mm)

Heat Transfer Area: 10 - 5500 ft² (1 - 500 m²) per unit

Shell Diameter: up to 100" (2500 mm)

Design Pressure: Full Vacuum to 600 psig (40 barg)

Design Temperature: -150 to 750 °F (-100 to 400 °C)

Typical design data; larger sizes & higher pressures or temperatures possible

Materials of Construction

We manufacture spiral heat exchangers from any material that can be cold formed and welded.

Standard: PVQ carbon steel, 304/304L, 316/316L, Duplex 2205

Higher Alloys: 904L, 254 SMO, AL6XN, Nickel Alloys, Titanium

Duplicate Replacements

We can design and build drop-in replacement spiral heat exchangers that are interchangeable with spirals built by other manufacturers.